Automation X

Automation for People

The SHOP4CF project examined how a software platform establishes the basis for human-centered automated solutions and how software tools increase robot safety.

Automated solutions are integral to industrial manufacturing. Such applications are often stand-alone solutions, though, and the data produced are used inconsistently or insufficiently. The connectivity of equipment and processes is exactly what makes Industry 4.0 possible in the first place. Extending this data connectivity beyond a company’s confines yields totally new opportunities for industry in Germany and Europe.

Humans play a key role in factories. Their creativity and flexibility are unrivaled. Their tasks and decision spaces are changing the same way their work environment is changing. Assistive solutions will increasingly help people in the future. There is a wide range here, from robots that perform complex operations fully automatically to augmented reality applications that help with assembly processes by, for instance, employing software solutions that process vast amounts of data to support decision-making.

Which solutions are used is highly individual and dependent on the particular company, its requirements, existing infrastructures and existing equipment. What is more, manufacturing already begins well before the factory gates when raw material are delivered, logistics services are coordinated and service and maintenance actions are subcontracted. This makes it expedient to design data-driven solutions interorganizationally and to pursue general standards for companies.

This is where the Smart Human Oriented Platform for Connected Factories SHOP4CF research project funded by the EU starts. In the project, around twenty research, academic, industry and SME partners developed a software platform with different components that cover a wide range of industrial requirements, particularly in the context of advanced, flexible and data-rich manufacturing.

“We want to reinforce people’s individual skills so that they can bring them into the factory better. For this to be successful, new technologies have to be consistently geared toward humans.”

Dr. José Saenz, Fraunhofer IFF

“We want to reinforce people’s individual skills so that they can bring them into the factory better. For this to be successful, new technologies have to be consistently geared toward humans,” says Dr. José Saenz, manager of the Department of Robotic Systems’ Assistive, Service and Industrial Robot Group. The research scientist researches innovative robotic applications at Fraunhofer IFF, particularly with an eye toward safe collaboration with humans.

Monotonous and very heavy physical labor can be fully automated. Humans cannot foreseeably be replaced in more complex activities that require creativity, great flexibility or a delicate sense of touch. Their work—supported by assistive solutions—takes on new meaning in factories. “The manufacturing of tomorrow will require both industrial resources and human capabilities. We intend to use the components of the SHOP4CF software platform to combine both and are aiming for complementarity between human labor and machines,” explains Saenz.

In the project, the consortium developed over thirty interoperable components for the platform, which are combined into a new architecture developed for the connected factory. This includes a data model to enable communication through different factories. All the components build upon this, consequently providing the basic implementation blocks for manufacturing solutions that assist humans with manufacturing. The components can be used to monitor tasks and resources as well as process configurations, for instance. Approval status and audits can also be represented and documented. The data in the systems are organized by tasks, e.g., a subprocess, action or operation performed by an actor in the system. Every action is consequently related to a specific task.

The data models were defined by specifying the most important attributes of everything used in a factory. Then they were assigned to the different tasks in a factory. The tasks were, in turn, classified as equipment, individuals and processes and divided into planning, execution and analysis phases.

The software components’ data are imported or exported from various sources, the digital twin, the factory MES or standard manual input.

Intended as a plug-and-play solution, Docker makes them ready for use quickly and easily. Advanced multilingual web applications facilitate intuitive use. The individual components can be downloaded easily from the Robotics and Automation MarketPlace RAMP platform, using various licensing terms.

The ethics of human-centeredness were a particular priority. The entire platform and every individual application were developed following an ethics-by-design approach. In the process, the consortium discussed such issues as self-determination and human dignity, among others. Data ownership and use were other issues considered. Some basic rules were established: Humans remain the determining and controlling entity in every stage of a process, their autonomy and rights remaining inviolable at all times. Data are collected only when absolutely necessary and one person’s actions are never revealed other employees. Privacy is protected at all times. Humans have the right to be informed about every hazard beforehand and to refuse to work with the assistance system. No one may be advantaged or disadvantaged by the applications because of personal attributes, either.

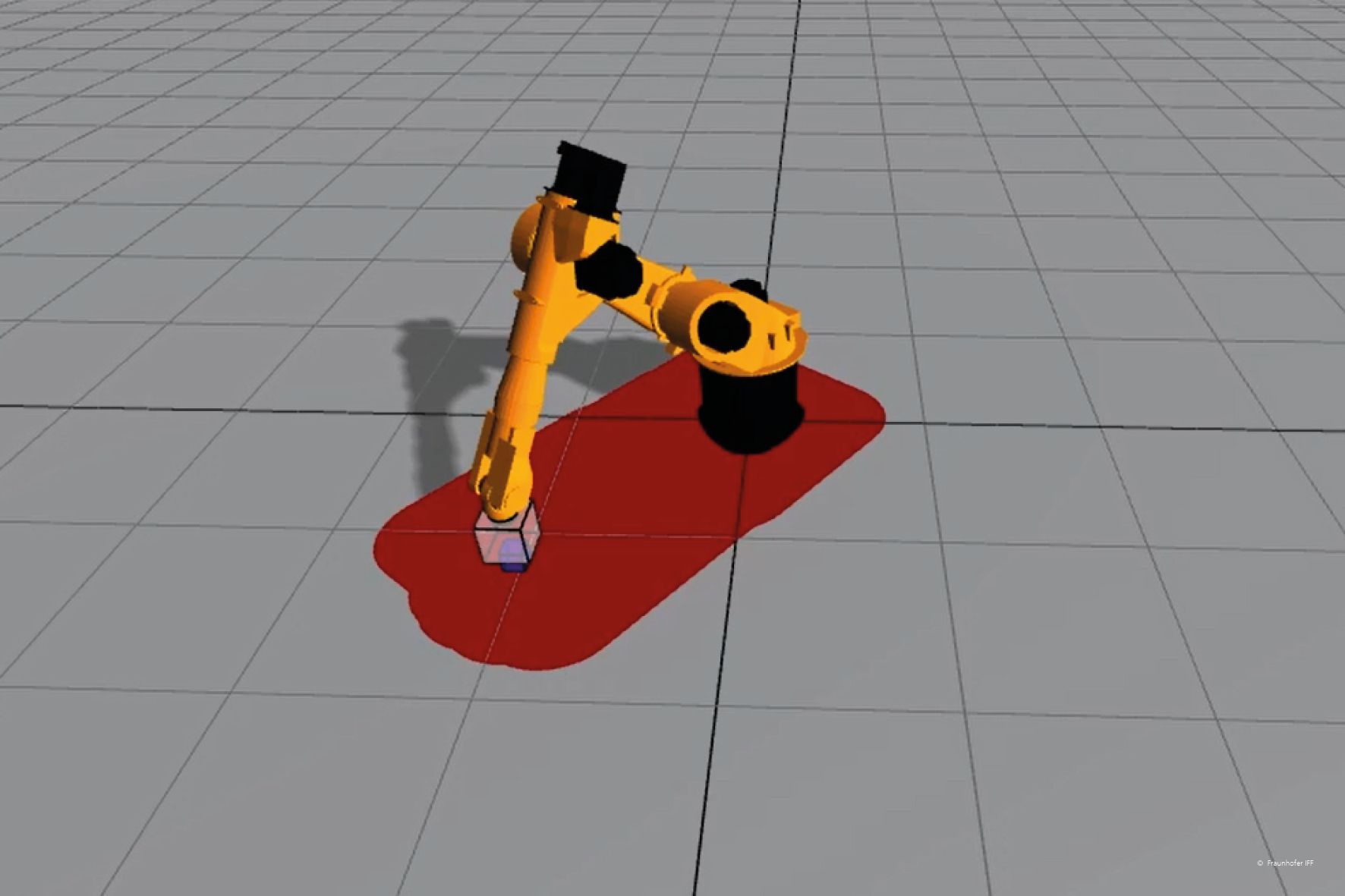

Ethics also include the human right to a safe and healthy working environment. An important aspect of that is the risk assessment of the technology used. “We at Fraunhofer IFF have specifically delved into the risk analysis of robotic applications. That is an ongoing issue for companies that use robots. Whenever a change is made to the robotic application, be that new programming or reprogramming or modifications to its design or workpieces because of a manufacturing change, the risks of collaboration with humans have to be reassessed,” explains Saenz. Changes to the intended kind of interaction with humans must be updated too.

“The software components can automatically modify components or processes in a certain application based on their integration into a connected factory architecture. Then a safety engineer can quickly and easily determine whether a new risk assessment is necessary since our software component responds to changes in processes or the design of the robotic application and directly displays the right places in the risk assessment. The data available provide the engineer a valid basis for decision-making,” the research scientist continues.

Guidance through the risk assessment process and documentation of hazards and risk mitigation actions are intuitive. Planned changes to the application are detected automatically by comparing the previous configuration and the safety engineer is made aware of this. All actions are documented in the system. The data available are consistently used in the company to ensure continuous conformance and to simplify safety-related decisions.

To establish the greatest acceptance possible, the consortium involved other contributors through open calls during the project period from early 2020 to the end of 2023. This produced a vibrant and steadily growing community of industrial companies, start-ups and research organizations.

The project deliverables will serve as the basis for applied industrial solutions and other research questions. “The platform is an important step toward standardization in the fields of cobotics, guided robots and the use of IoT-devices on factory floors. Along with a dedicated community, this is essential to the establishment of broad acceptance of such solutions in industry,” says Dr. José Saenz, summing up.

Funding information: SHOP4CF was funded by the European Union’s research and innovation funding program Horizon 2020 as part of grant agreement number 873087.