Digital Twin Family

Taking Collaboration Further

Interorganizational platform enables information and knowledge sharing with a manufacturing plant’s digital twin

Accounting for around one quarter of the gross value added, manufacturing companies in Germany are a mainstay of the economy. Globalization is increasing competitive and cost pressure, though. Customers desire custom products and sustainability standards consonant with resource efficiency and new circular strategies are on the rise. All this is causing companies difficulties. They have to modify manufacturing processes and upgrade or retrofit equipment. At the same time, their manufacturing systems are growing more and more complex technically while control, servicing and maintenance are growing more demanding.

Machines and equipment in industrial companies are increasingly being equipped with information and communications technologies and interconnected. The level of digitalization of industrial manufacturing and value chains is continuing to rise strongly. Industry 4.0 is becoming reality and routine. Companies are hoping the larger quantity of information available will bring options for optimization. A plant’s productivity is top priority for all of them. It ensures value creation and thus competitiveness and a facility’s future.

“Collaborative partnerships have to affect the value creation process positively, helping to boost the plant’s cost effectiveness.”

Stephan Dassow, Metop GmbH

A manufacturing plant’s life cycle extends from its design to its construction, its integration and connection and its ongoing operation, including maintenance, through eventual decommissioning and reuse of the parts. That is why quite different companies are involved in the different phases of the life cycle. Ideally, they work hand-in-hand to run the entire plant efficiently and protect it from downtimes over the long run. This necessitates valid digital models and other data, such as process and simulation data or manufacturing parameters.

Information and digital data management is growing increasingly important in operation and management. At the same time, plant functions and causal relationships are growing harder to grasp and understand. Maintenance work is often subcontracted and continual refinements of equipment require close communication between manufacturers, operators and service contractors. The systems view of the whole is lost. Information is distributed and often incomplete or outdated. This problem keeps growing during the product life cycle.

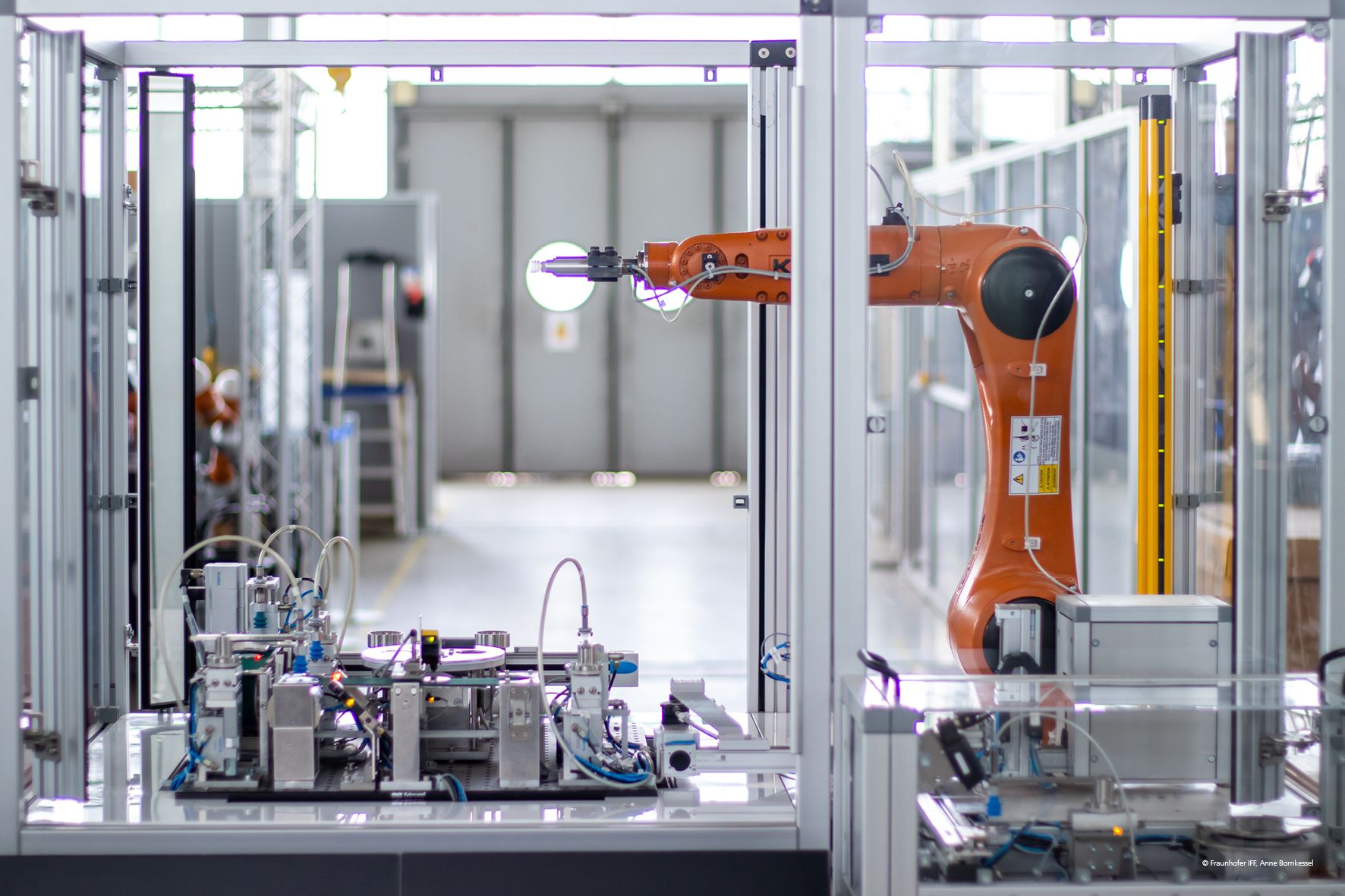

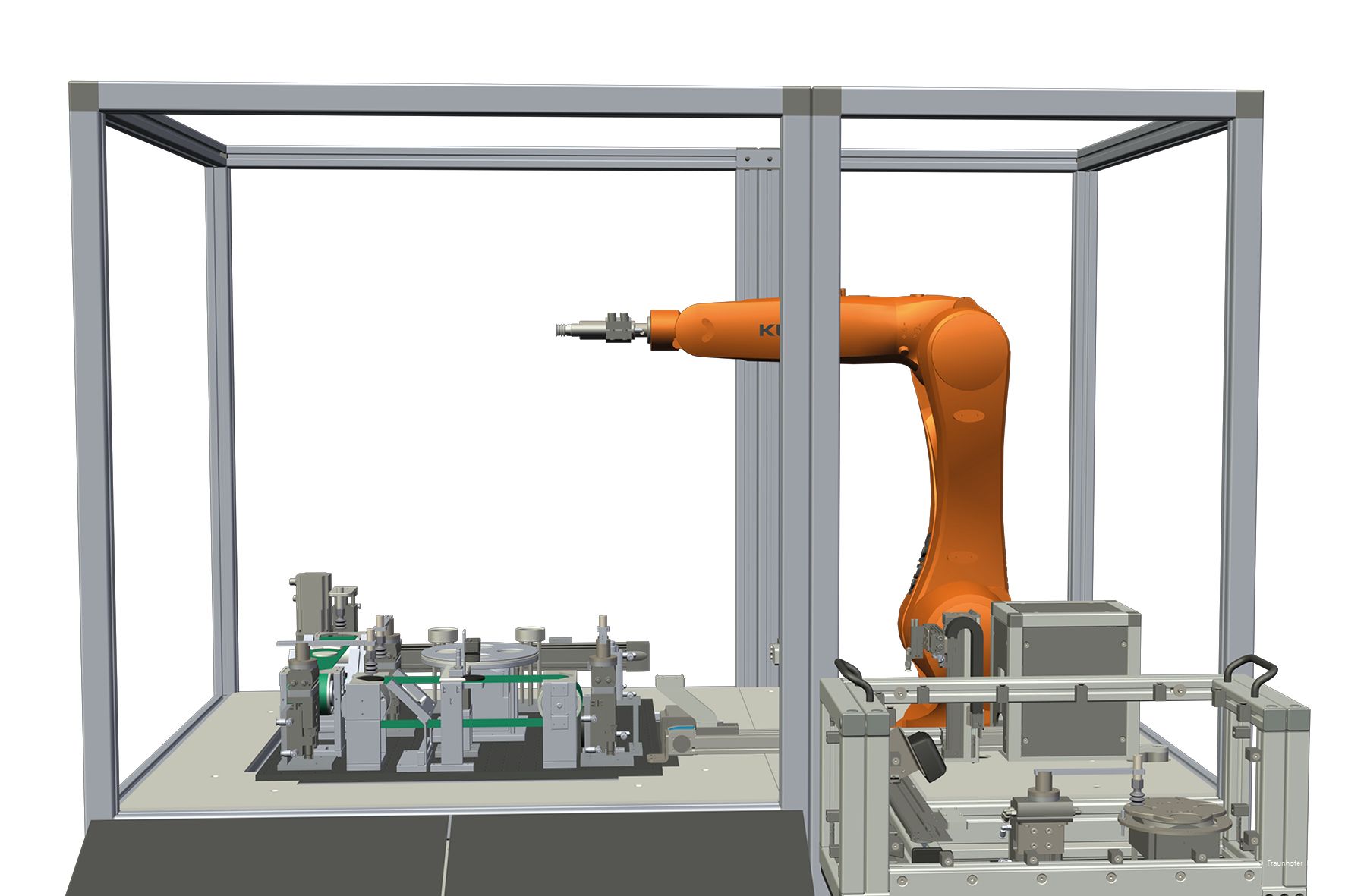

One approach is a collaboration platform that makes a shared standard dataset available to everyone involved throughout the entire plant life cycle. This was the starting point of the project Designing Interorganizational Collaborative Networks with the Digital Twin or NedZ, which ran from April 2020 until its successful completion in March 2023. In the project, a data-based collaborative network was developed together with several project partners from manufacturing, industrial engineering and research. Industrial engineering expert Brandenburg University of Technology Cottbus-Senftenberg, implementation partner machinery manufacturer SM Calvörde Sondermaschinenbau GmbH & Co. KG, data sovereignty and business model experts Metop GmbH and Klesyma GmbH and the implementation partners Rusche-Zubringetechnik and SIS GmbH were involved. Fraunhofer IFF was the coordinator.

“Aspects of workspace design, decision-making options and changed workload and demand situations resulting from digitalization are growing more and more important with, among other things, an eye toward demographic factors as well.”

Dr. Anna-Sophia Henke, BTU Cottbus-Senftenberg

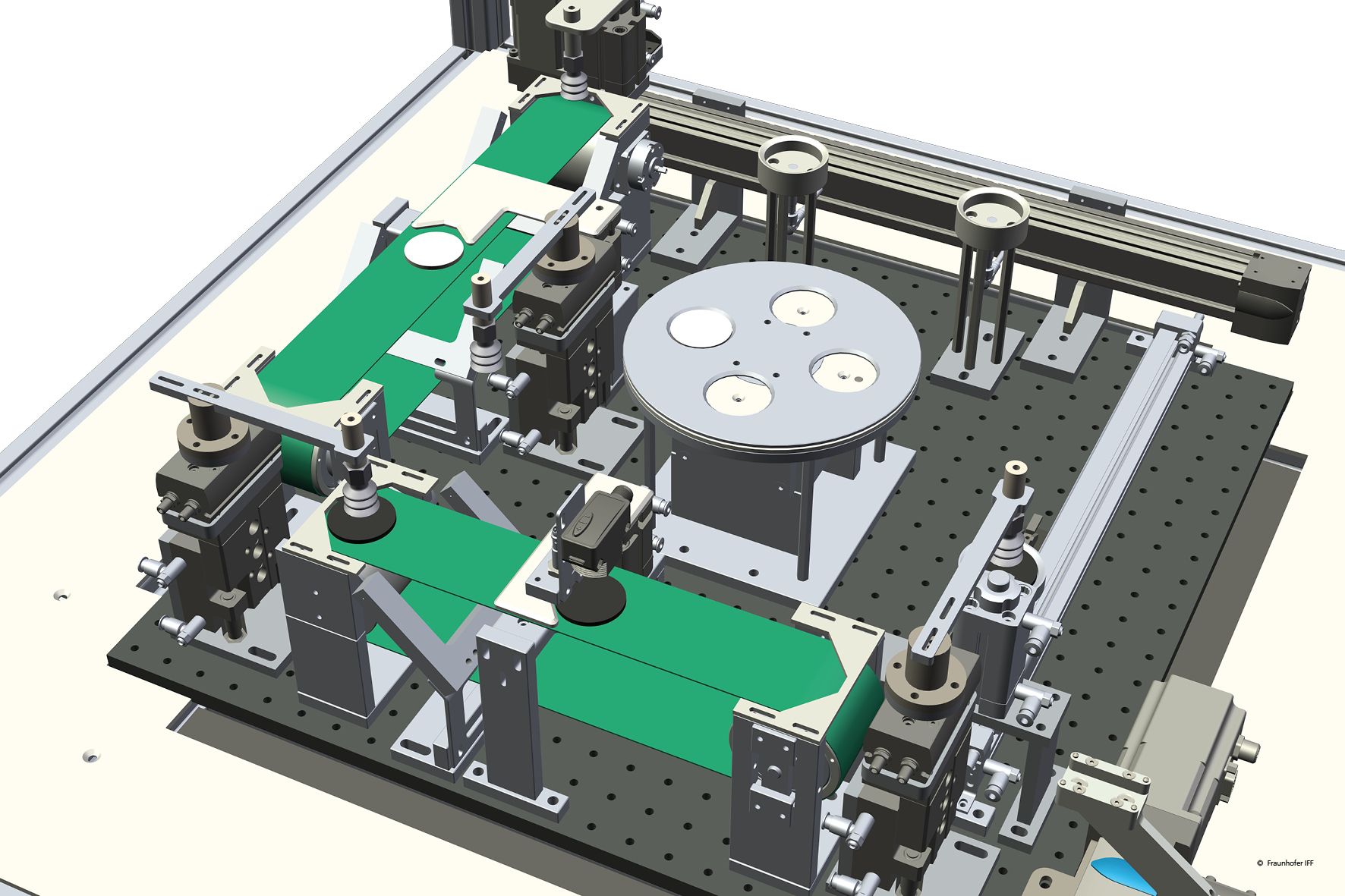

The objective was to identify up-to-date ways of working based on a prototype digital twin of a manufacturing plant for purposes of interorganizational collaboration. All project partners shared this collaboration platform, providing and managing data. The primary objective was to improve plant operation, consequently increasing value creation among the companies involved.

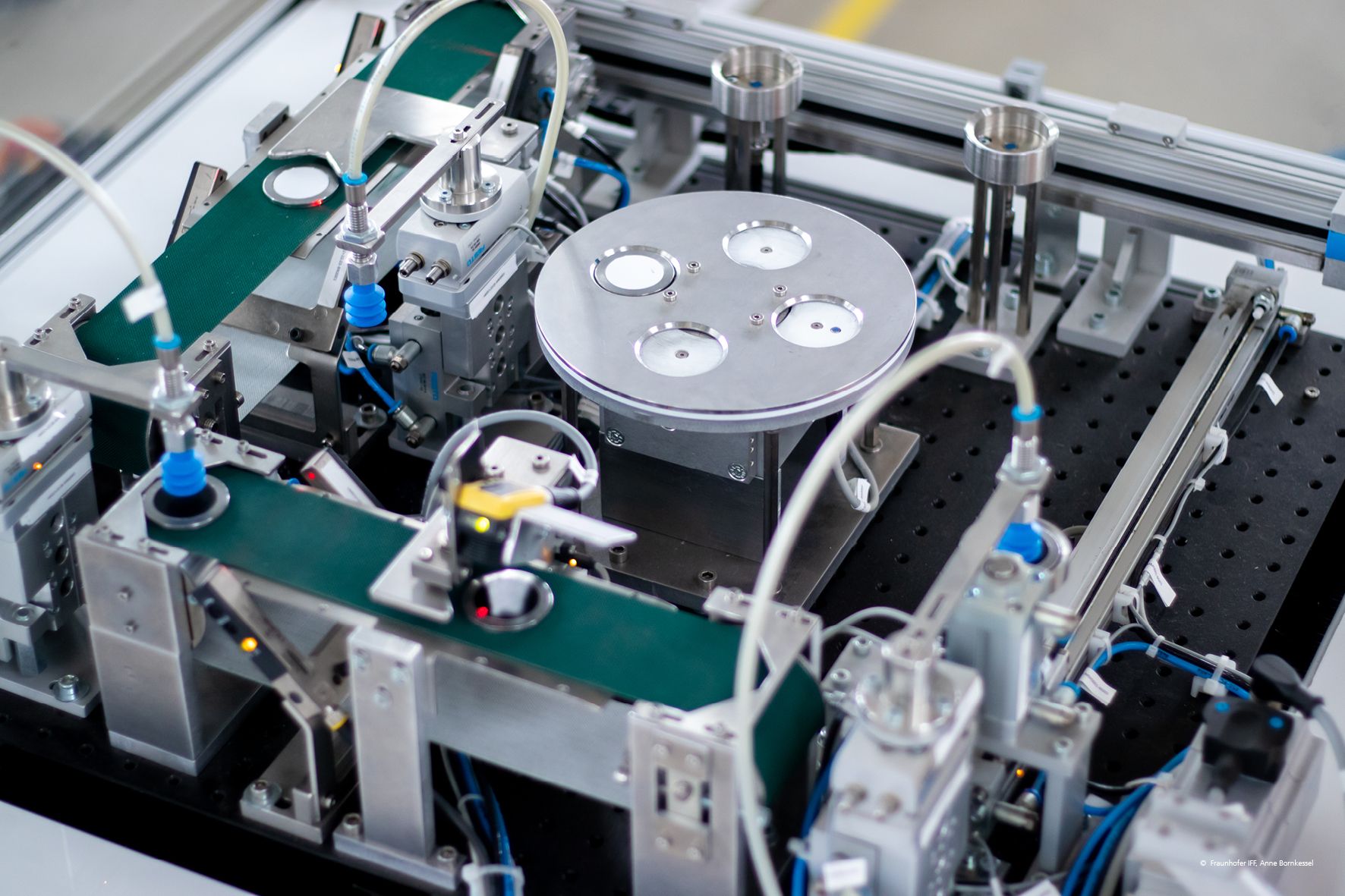

Based on this network, the implementation partners developed a value-creation system modeled after a specific manufacturing plant. Then the current value-creation process was analyzed and, building upon this, key requirements and constraints of a data-based collaborative network were identified. These findings were used to identify use cases that were implemented in practice and designed for the new requirements.

The collaborative network ought to be seen as an assistance system. All the specialists who work with it have a shared, global view of “their” manufacturing plant. Collaboration is simplified. The digital twin is the main base of information and work, comprising structural information and documents. It additionally reproduces the plant’s real state in real time. This makes it possible to design processes and services interorganizationally, transparently and flexibly. Since plant operation is a key task in value creation, the digital twin also becomes the key element of long-range efficiency and innovation. Metop GmbH specifically studied this factor in the project. “We analyzed the product life cycle and scrutinized the business models of everyone involved in the plant, such as plant builders and operators as well as maintenance technicians,” explains Stephan Dassow, purchasing director and project manager at Metop GmbH. “We wanted to know what impacts each of the forms of collaboration have. After all, collaborative partnerships have to affect the value creation process positively, helping to boost the plant’s cost effectiveness,” continues Dassow. Ensuring data sovereignty at all times was important. “Each project partner decided themselves who can see their data. Such a thing is essential for interorganizational collaboration,” says Dassow, describing the approach.

Since information and data are often a decisive competitive edge, their protection was a particularly important requirement in the NedZ project. For this reason, all the project partners involved conducted a risk assessment of the digital twin based on the objectives of information security: confidentiality, integrity and availability.

Not only new kinds of value creation but also new forms of collaboration and work organization arise. The collaboration platform affects work processes, requiring new digital and social skills and employee acceptance. “We supported the whole project with industrial engineering. Ways collaborative networks can be designed were demonstrated based on the company’s respective processes. It was important to factor possible impacts on the work process and employees into it,” says Dr. Anna-Sophia Henke, research associate on the work organization team and project manager at Brandenburg University of Technology Cottbus-Senftenberg. Requirements and workloads that changed for the specialists involved were primary issues. “Aspects of workspace design, decision-making options and changed workload and demand situations resulting from digitalization are growing more and more important, among other things, with an eye toward demographic factors as well,” explains Henke.

“We at Fraunhofer IFF developed a web-based solution for this, which factors in all the requirements.”

Torsten Böhme, Fraunhofer IFF

Efficient processes and intuitive data handling require an appropriate software solution. “We at Fraunhofer IFF developed a web-based solution for this, which factors in all the requirements,” says Torsten Böhme, NedZ project manager at Fraunhofer IFF. The digital twin’s data were consolidated and made accessible to everyone involved according to their particular authorization in a front-end. Usability, controllability and error management were just as important as protecting data from unauthorized access.

The NedZ project combined social and technical innovations, incorporating the factors essential to interorganizational networks. Long-term collaborative networks based on digital twins can improve work organization at companies and optimize maintenance actions for manufacturing plants. What is more, such a network can also be the starting point for new data-based services.

Funding information: The research project is being funded by the Federal Ministry of Education and Research (BMBF) and the European Social Fund (ESF) as part of its Future of Work program (grant number: 02L18B500ff.) and overseen by Projektträger Karlsruhe (PTKA).