Superhuman Operator

Defect-Free Single Item Manufacturing

How augmented reality is assisting with the assembly of clamping systems in custom equipment manufacturing

Wood is a sustainable resource and data on its increasing harvesting and processing demonstrate its growing popularity. Its potential uses are wide ranging. The natural material is used particularly heavily in construction, for instance, for window frames, doors and roof framing. Another major consumer is the furniture industry, wood being its main material. Both industries process large quantities of solid wood, usually spruce, pine or beech.

Interconnected plant systems are used to process solid wood from the log to the finished product. Only a handful of companies have the capability to build such giant and highly complex custom equipment for solid wood processing. One of the world’s largest has its headquarters in Tauberbischofsheim, Baden-Württemberg. Michael Weinig AG has been building wood processing equipment for major furniture manufacturers and the construction industry for nearly eighty years.

“A plant system comprises thousands of component parts in many hundreds of assemblies. It is custom- and purpose-built. We use CNC machines to manufacture the individual assemblies.”

André Veith, Michael Weinig AG

“A plant system comprises thousands of component parts in many hundreds of assemblies. It is custom- and purpose-built. We use CNC machines to manufacture the individual assemblies,” explains Andre Veith, head of Process Management and Infrastructure/CIP at Michael Weinig AG.

CNC machining requires fixtures in which machined parts can be clamped. Such clamping systems can comprise very different elements, such as stoppers, strap clamps, clamping claws or vises. They are custom-built for each part and assembled manually. These clamping systems of completely different size, weight and complexity have to be bolted together absolutely defect-free and in the right position. “Although we have exact 3D models of the fixture parts, which our employees see on monitors, assembly requires knowledge and experience. At present, we already have all upstream processes, such as virtual clamping system development, CAM programming and simulation of the real NC code, in a digital twin and all clamping systems and tool management processes have been digitalized. We are still missing the transition from the virtual to the real world in fixture development, though,” says Veith, continuing. All the same, humans make mistakes during assembly since the physical fixture part is never directly compared with the digital model. Despite working carefully, the CNC machine can be damaged when a clamping fixture has been assembled incorrectly or a part has been clamped incorrectly and consequently does not exactly match the machine’s programmed sequence. Unwanted collisions occur in feeds and speeds. At worst, the machine is damaged so severely that it breaks down entirely and has to be repaired. “One single CNC machine downtime can quickly cost five figures,” says Veith, describing the problem.

A few years ago, research scientists at Fraunhofer IFF developed a solution for this for another custom equipment manufacturer. Kolbus GmbH & Co. KG in Rahden, East Westphalia custom manufactures equipment for book cover and packaging manufacturing and faced a challenge like Michael Weinig AG, which also had to do with custom assembly processes for clamping systems.

“We developed a technical solution in which a digital assistance system assists specialized staff.”

Steffen Sauer, Fraunhofer IFF

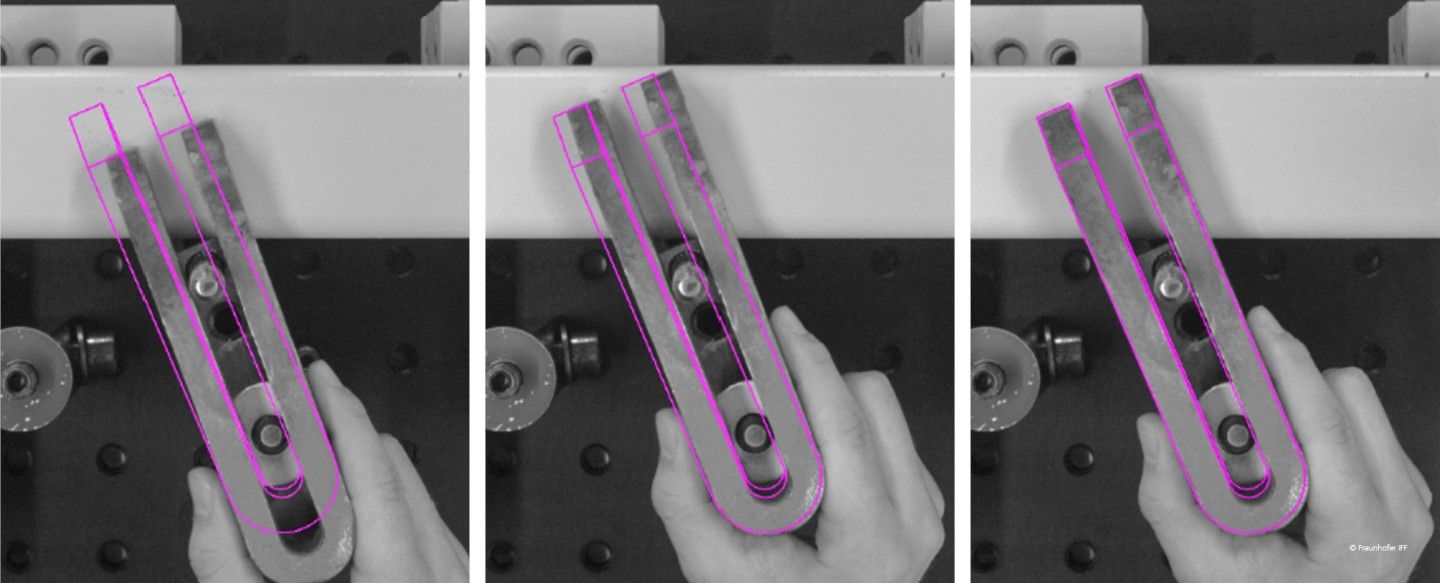

“We developed a technical solution in which a digital assistance system assists specialized staff. A camera takes a picture of the work zone. Augmented reality overlays this image with the 3D model of the assembly. This enables the employee to verify the position and correctness of the individual component parts in real time during assembly,” says Steffen Sauer, project manager at Fraunhofer IFF, describing the technical solution. The system has a tolerance of just 0.3 mm. Every part is overlaid singly and confirmed when it is correctly in place in the assembly, before moving on to the next part. This virtually eliminates human error in the assembly of the fixture for the CNC machine. “Since its first use at Kolbus, there have not been any CNC machine collisions caused by humans. Moreover, this system functions very intuitively. The training required is minimal,” reports Sauer. These benefits convinced Michael Weinig AG to contract such a custom assistance system from Fraunhofer IFF.

Kolbus has gathered so much experience with the assistance system in the meantime that their knowledge about workspace design was incorporated into the solution for Michael Weinig AG. “We launched a joint venture with Kolbus. They bring practical experience with workspace design and we develop the right software for Michael Weinig AG,” says the IFF research scientist, continuing.

Collaboration with the Austrian company Pimpel proved particularly productive too. They are responsible for providing CAD/CAM data at Michael Weinig AG with the software CHECKitB4 they developed. CHECKitB4 can model digital twins (3D solids including kinematic axes) of strap clamps, clamping claws, vises and even machine tools 1:1. This makes it very easy to prepare the workpiece setup for the particular machine and verify its feasibility. Fascinated by the possibilities of a continuous digital chain from design to machining, Pimpel refined its software in close consultation with Fraunhofer IFF. It is now possible to export assembly instructions from the CAD/CAM software with minimum preparation and to load them right into the assistance software.

The assistance system enables manufacturing workers to learn complex operations quickly and easily. A digital process running parallel in real time is added to manual manufacturing. This combines the advantages of both worlds—highly custom manufacturing by hand and clearly defined, defect-free digital processes. In addition to simply assembling units, people are also given control tasks in the process sequence here. Humans remain essential, making the decisions—and are assisted effectively by the assistance system.

Assisted clamping system assembly has one more advantage: Until now, a machine has had to run through the machining program in single-step mode when machining a part for the first time. Knowledgeable specialists supervise this time-consuming, non-value and inefficient step. This time-consuming CNC machine first run is now omitted completely. The workpiece can be inserted in the machine as soon as the clamping system has been installed. Data are updated in real time and available for the downstream manufacturing processes.

Employees’ knowledge and experience are often crucial to a company’s economic performance, particularly in highly customized assembly processes, such as those in custom equipment manufacturing. Assisted clamping system assembly helps teach frequently changing assembly processes quickly and intuitively. Unqualified or underqualified employees can be quickly taught this job with the assistance system. This broadens the fields of activity for humans and makes staff scheduling flexible. All this increases the attractiveness of factory jobs when skilled labor is in short supply.

Assisted clamping system assembly has been a complete success at Michael Weinig AG. “We initially equipped two work cells with the new system. We left another work cell unchanged as backup,” says Andre Veith, adding, “But now nobody wants to work there any longer. They all just want to use the new technology. Clearly, this will not be the last Fraunhofer IFF work cell at Weinig. Other potential uses are being discussed internally. We are currently looking into whether we can also integrate the technology in the mechanical room or in pallet clamping for heavy machinery.”