2023 Highlight Projects

Automation for People

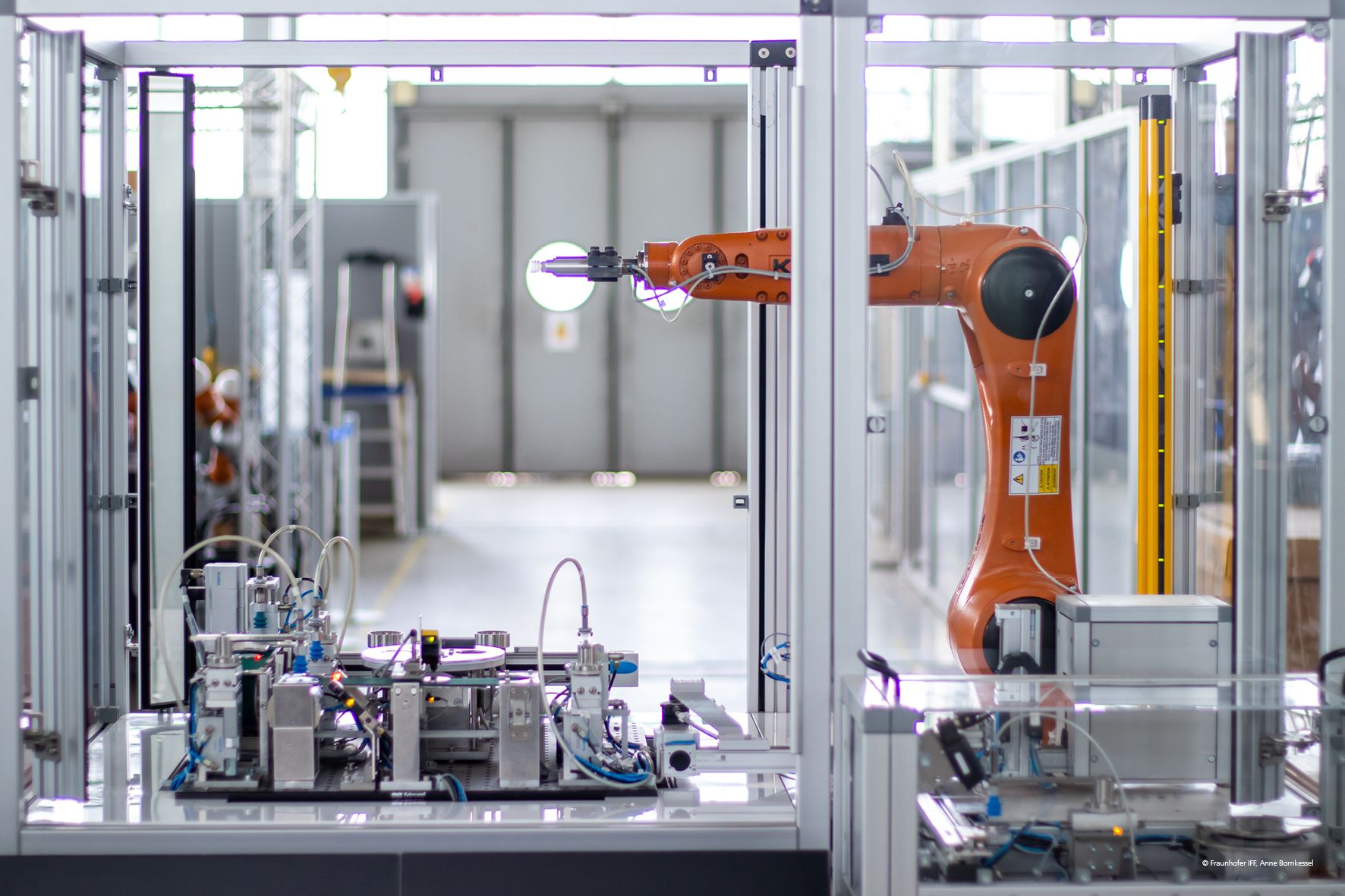

The SHOP4CF project examined how a software platform establishes the basis for human-centered automated solutions and how software tools increase robot safety.

Staying Competitive

A feasibility study for logistics provider MOSOLF reveals that sustainable energy supply solutions stay cost-effective.

Defect-Free Single Item Manufacturing

How augmented reality is assisting with the assembly of clamping systems in custom equipment manufacturing

Taking Collaboration Further

Interorganizational platform enables information and knowledge sharing with a manufacturing plant’s digital twin

Discover More Projects

Automation X

As a realm of assistive robotics, public space confronts manufacturers and users with particular challenges.

Companies and research organizations in the Rokit excellence cluster are developing wide-ranging support services for this intended application. The goal is to facilitate the integration of such robots in public settings.

Fraunhofer IFF is concentrating on assessing the safety of assistive robots. Various test and validation practices are being produced, which are being field tested under real conditions and evaluated.

Rokit will continue as a resource center for assistive robots after the project ends in September 2025.

Contact: Dr. Roland Behrens, roland.behrens(at)iff.fraunhofer.de

Net Zero X

Successful structural change in a coal-mining region: The coal phaseout is an opportunity to transform coal-mining regions into economically and environmentally thriving regions. The two research organizations Fraunhofer IFF and RWTH Aachen are facilitating technology transfer during this change in the project Research and Technology Transfer in the Transformation Process of Structural Change in Saxony-Anhalt WIP.

The project is intended to empower municipalities and regions of the Central German coal-mining region in Saxony-Anhalt to develop long-term development strategies for energy and land-use planning and to initiate, implement and evaluate suitable projects. It is transfering knowledge about and practices of economically expedient and environmentally sustainable planning and development strategies. Active interconnectedness of municipalities and communities will facilitate knowledge and experience sharing.

The project started on July 1, 2023 and will run until June 30, 2026.

Contact: Andreas Höpfner, andreas.hoepfner(at)iff.fraunhofer.de

Funding information: The project is being funded by the Federal Ministry for Economic Affairs and Climate action based on a resolution of the German Bundestag.

Automation X

VILSA-BRUNNEN Otto Rodekohr GmbH added a new high bay warehouse to its facility in Bruchhausen-Vilsen, Lower Saxony. With room for 46,500 pallets, it is one of the largest in Northern Germany and an important milestone in the beverage manufacturer’s more than 111-year history.

To utilize this warehouse’s capacities optimally in a highly volatile and somewhat seasonal market and to ensure as close to 100% delivery capability as possible, the long-standing company contracted Fraunhofer IFF to perform data analyses and process simulations for production planning and warehouse management and to study how they can be synchronized and optimized strategically and tactically.

The project ran from October to December 2023.

Contact: Thomas Dengler, thomas.dengler(at)iff.fraunhofer.de

Digital Twin Family

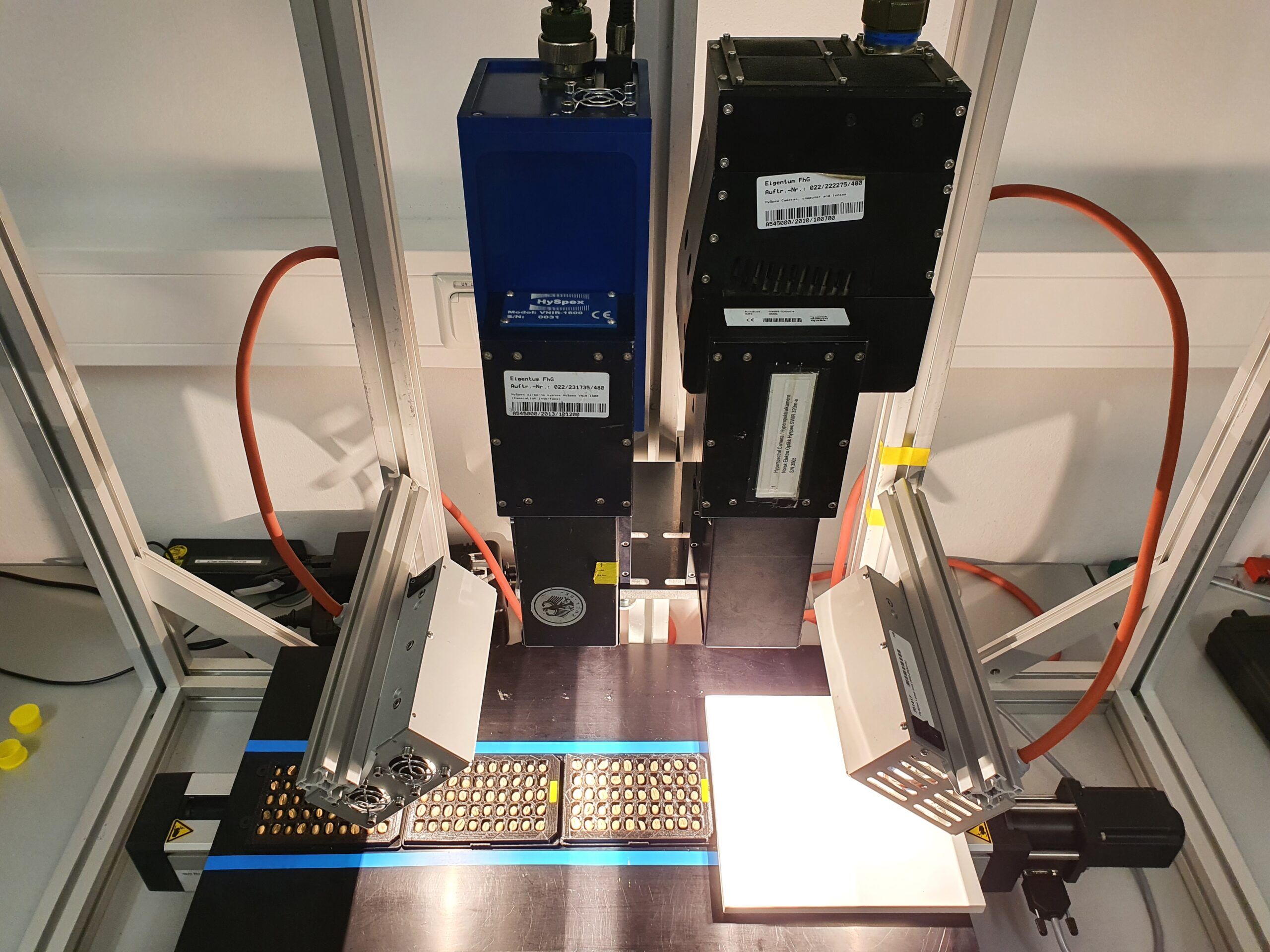

The identification of items’ chemical composition has numerous applications, such as food quality control, plant health assessment, counterfeit detection and recycling in the circular economy.

Together with the University of Bielefeld, Fraunhofer IFF used optical spectroscopy and AI data analysis to develop new methods to relay AI models between different pieces of sensor hardware in the TiM research project. This is significantly less expensive than creating a new AI model for every sensor.

Contact: Patrick Menz, patrick.menz@iff.fraunhofer.de

Funding information: BMBF project (05M20PBA, 05M20AFA – Desy)

Automation X

Fraunhofer IFF developed a sensor system that recognizes people and their gestures for SIASUN Virtual Reality Industrial Technology Research Institute in China.

A cobot equipped with the system will lighten the workloads of guest guides at the institute’s visitor center. The mobile platform’s tracking system follows a guide fully autonomously. The camera-based gesture recognition enables the cobot to mimic “its” human’s gestures.

Contact: Dr. Christian Vogel, christian.vogel(at)iff.fraunhofer.de

Digital Twin Family

Among other things, wings are attached to the fuselages of various aircraft types in the four final assembly lines at the Airbus plant in Hamburg. The perfect mating of the extremely large parts includes numerous individual inspection and alignment processes. Highly trained employees primarily measure the numerous measuring points manually. This demands great care and their work requires substantial time.

Fraunhofer technology will be ushering in improvements here in the future. The AirBox was field tested at the plant in several individual projects. It is intended to monitor wing assembly subprocesses automatically and in real time with sensors. The digital data are collected, visualized and used to control the mating process. Sensor-assisted process monitoring is more ergonomic and saves time too.

Contact: Dr. Olaf Poenicke, olaf.poenicke(at)iff.fraunhofer.de

Automation X

Explosive ordnance and land mines still pose a significant danger long after a war. Merely the suspicion that land is contaminated restricts its use significantly, e.g., for farming or development.

Freeing such land from unexploded ordnance and dangerous munition remnants takes decades and is expensive and extremely dangerous.

The solution developed in the AutoDrone UA project overflies land with large drone swarms and analyzes it five times faster, without putting ground-controlled systems, mine detection dogs or people at risk.

Fraunhofer IFF developed the drone control software for explosive ordnance disposal specialists Tauber Geo-Consult.

Contact: Prof. Klaus Richter, klaus.richter(at)iff.fraunhofer.de

Digital Twin Family

Predictively controlling processing plants: Even though the processes of solids process engineering have been established in industry for decades, the monitoring and control of the processes of manufacturing plants in the chemical or food industry are continuously facing new challenges to avoid undesired process conditions and rejects and to boost efficiency.

Series of tests are being performed on laboratory plants and subsequently scaled based on the experiences.

In the TwinGuide project, a digital plant twin is being combined with (real-time) simulations of the processes running inside. This combination yields a digital twin with intelligent processes that makes it possible to adjust process parameters precisely and control processes predictively.

This digital twin makes it possible to model processes in plants on a large-scale quickly and accurately. Forecasts of the further manufacturing run and compliance with manufacturing specifications make it possible to operate manufacturing plants resource-efficiently.

Contact: Dr. Andreas Herzog, andreas.herzog(at)iff.fraunhofer.de

Automation X

More than 2500 signal boxes are needed to control rail operation in Germany. More than 1000 of them are interlockings. Interlockings specify route.

These safety-related components are painstakingly made by hand at the technology leader Thales Group. Their manufacture requires intense concentration and absolutely flawless work.

Fraunhofer IFF conducted a feasibility study to ascertain how to lighten employees’ complex quality inspection workload in the future. Prototype scanning systems were developed, which perform the required inspections on interlockings automatically. Both camera-based and precision solution have to be found for this.

The project will run around one year and end in mid-2024.

Contact: Silvio Sperling, silvio.sperling(at)iff.fraunhofer.de